Global IOT in Chemical Market Size, Trends & Analysis - Forecasts to 2029 By Technology (Enabling Technology and Operational Technology), By Application (Chemicals, Food & Beverages, Mining & Metals, Paper & Pulp, and Pharmaceuticals), and By Region (North America, Asia Pacific, Central & South America, Europe, and Middle East and Africa), Competitive Landscape, Company Market Share Analysis, and End User Analysis

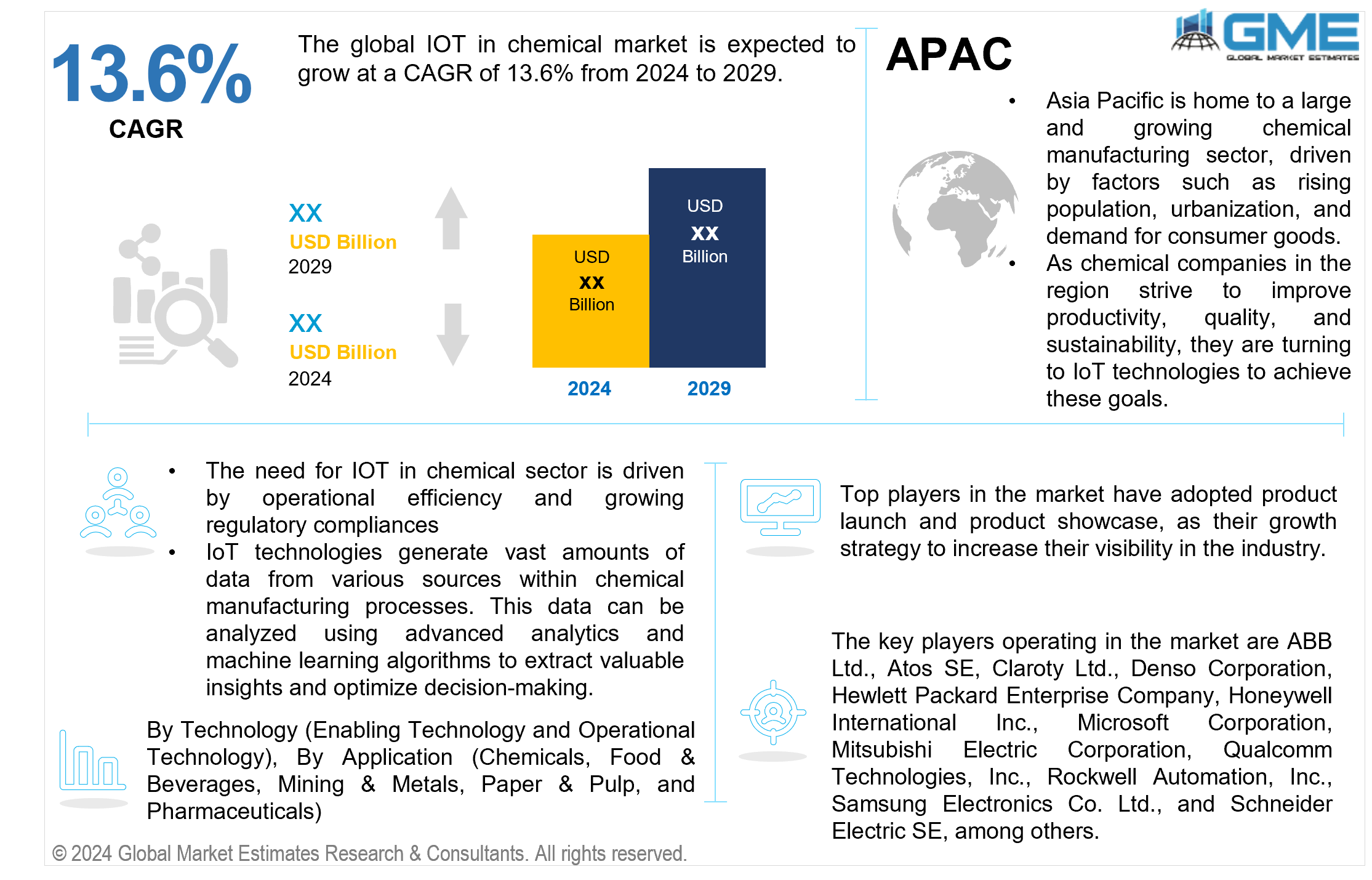

The global IOT in chemical market is expected to grow at a CAGR of 13.6% from 2024 to 2029. The Internet of Things (IoT) comprises web-enabled smart devices that use embedded systems, such as processors, sensors, and communication hardware, to gather, process, and analyze data collected. Chemical inventories in storage tanks and warehouses can be monitored using IoT-enabled sensors.

The market is driven by rising demand for operational efficiency and growing regulatory compliances. Chemical manufacturers are increasingly seeking ways to enhance operational efficiency and reduce production costs. IoT technologies offer real-time monitoring and control capabilities, enabling companies to optimize processes, minimize downtime, and improve resource utilization. IoT sensors and monitoring devices help chemical companies comply with regulations by providing accurate data on environmental conditions, emissions, and workplace safety. Utilizing IoT solutions enables companies to observe and document compliance metrics instantly, mitigating the possibility of regulatory breaches and subsequent penalties. IoT technologies generate vast amounts of data from various sources within chemical manufacturing processes. This data can be analyzed using advanced analytics and machine learning algorithms to extract valuable insights and optimize decision-making.

The market faces restraints such as security and privacy issues. Given the sensitive nature of data collected by IoT sensors in the chemical industry, such as process parameters, formulations, and product specifications, ensuring robust cybersecurity measures is paramount.

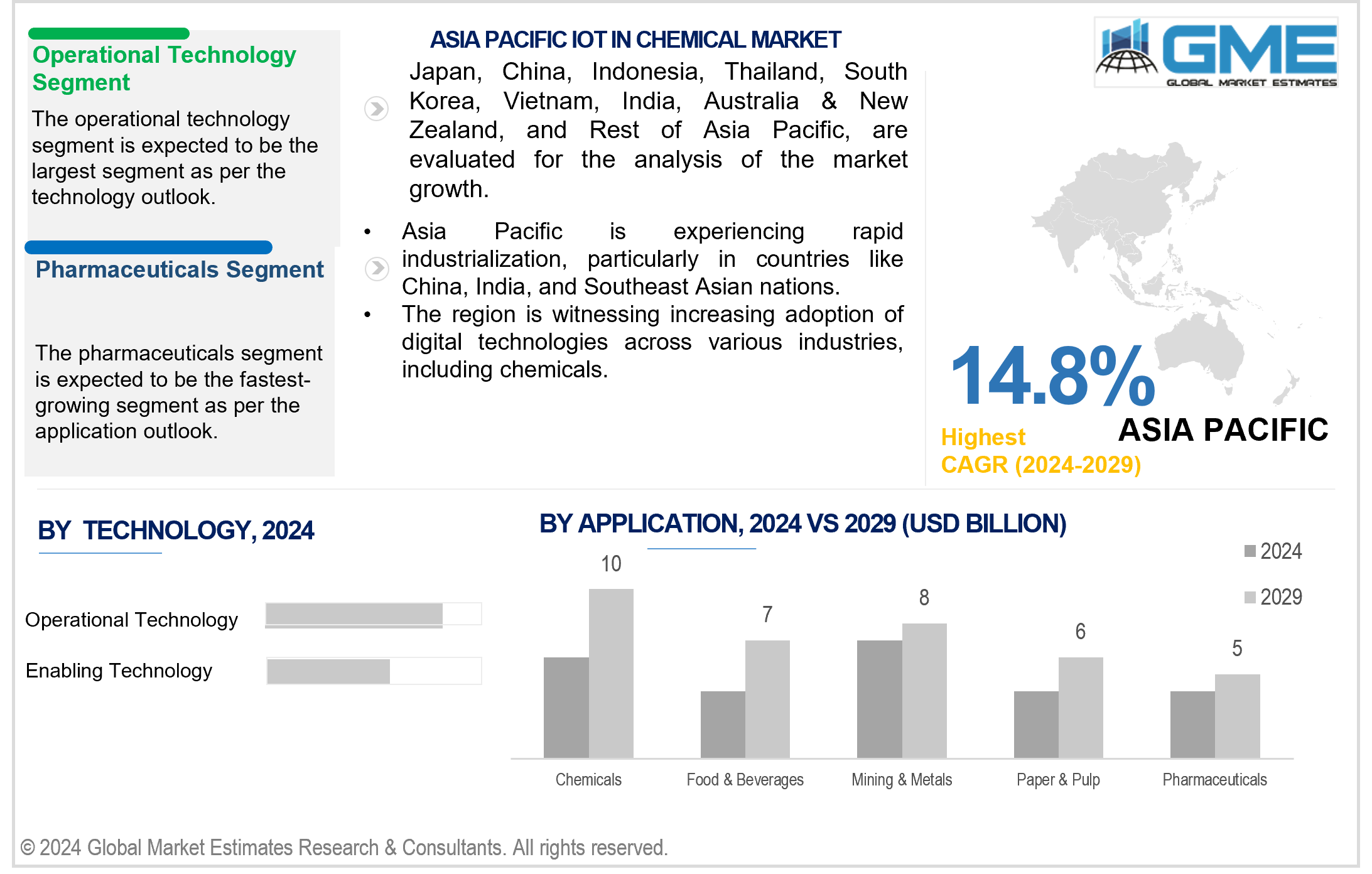

Based on technology, the market is segmented into enabling technology and operational technology. The operational technology segment is expected to hold the largest share of the market during the forecast period. This segment dominates the IoT in chemical market as it fulfills critical industry requirements like real-time monitoring, process control, and automation. Through IOT solutions, chemical companies optimize production, enhance efficiency, ensure safety compliance, and mitigate operational risks. These capabilities empower firms to meet industry demands effectively and maintain a competitive edge.

The enabling technology segment is projected to grow fastest during the forecast period. This growth is fueled by the development of increasingly sophisticated and scalable solutions. As chemical firms acknowledge the value of IoT in fostering digital transformation and competitive edge, the demand for enabling technologies supporting effective deployment and management of IoT systems is on the rise.

Based on application, the market is segmented into chemicals, food & beverages, mining & metals, paper & pulp, and pharmaceuticals. The chemicals segment is expected to hold the largest share of the market over the forecast period. Chemical manufacturing processes often involve complex operations and require precise monitoring and control of various parameters, making IoT technologies particularly significant in this industry.

The pharmaceuticals segment is projected to grow fastest during the forecast period. The pharmaceutical industry is increasingly adopting IoT solutions to improve manufacturing efficiency, ensure regulatory compliance, and enhance product quality. With advancements in IoT technology and increasing focus on pharmaceutical manufacturing automation and digitization, the adoption of IoT in the pharmaceutical sector is expected to accelerate rapidly.

North America is analyzed to be the largest region in the global IOT in chemical market during the forecast period. The region is a significant market for IoT solutions within the chemical industry due to its abundance of chemical manufacturing enterprises and its reputation for embracing advanced technologies at an early stage. The United States is the dominant nation in this region, with the biggest market share.

Asia Pacific is analyzed to be the fastest-growing region in the global IOT in chemical market during the forecast period. Asia Pacific is experiencing rapid industrialization, particularly in countries like China, India, and Southeast Asian nations. The region is witnessing increasing adoption of digital technologies across various industries, including chemicals. Asia Pacific is home to a large and growing chemical manufacturing sector, driven by rising population, urbanization, and demand for consumer goods which are dependent on the chemical industry. As chemical companies in the region strive to improve productivity, quality, and sustainability, they are turning to IoT technologies to achieve these goals.

ABB Ltd., Atos SE, Claroty Ltd., Denso Corporation, Hewlett Packard Enterprise Company, Honeywell International Inc., Microsoft Corporation, Mitsubishi Electric Corporation, Qualcomm Technologies, Inc., Rockwell Automation, Inc., Samsung Electronics Co. Ltd., and Schneider Electric SE, among others, are some of the key players operating in the global market.

Please note: This is not an exhaustive list of companies profiled in the report.

1 STRATEGIC INSIGHTS ON NEW REVENUE POCKETS

1.1 Strategic Opportunity & Attractiveness Analysis

1.1.1 Hot Revenue Pockets

1.1.2 Market Attractiveness Score

1.1.3 Revenue Impacting Opportunity

1.1.4 High Growing Region/Country

1.1.5 Competitor Analysis

1.1.6 Consumer Analysis

1.2 Global Market Estimates' View

1.3 Strategic Insights across Business Functions

1.3.1 For Chief Executive Officers

1.3.2 For Chief Marketing Officers

1.3.3 For Chief Strategy Officers

1.4 Evaluate the Potential of your Existing Business Lines vs. New Lines to Enter Into

2 TECHNOLOGICAL TRENDS

2.1 Technological Adoption Rate

2.2 Current Trend Impact Analysis

2.3 Future Trend Impact Analysis

3 GLOBAL MARKET OUTLOOK

3.1 Market Pyramid Analysis

3.1.1 Introduction

3.1.2 Adjacent Market Opportunities

3.1.3 Ancillary Market Opportunities

3.2 Demand Side Analysis

3.2.1 Market Drivers: Impact Analysis

3.2.2 Market Restraints: Impact Analysis

3.2.3 Market Opportunities: Impact Analysis

3.2.4 Market Challenges: Impact Analysis

3.3 Supply Side Analysis

3.3.1 Porter’s Five Forces Analysis

3.3.1.1 Threat of New Entrants

3.3.1.2 Threat of New Substitutes

3.3.1.3 Bargaining Power of Suppliers

3.3.1.4 Bargaining Power of Buyers

3.3.1.5 Intensity of Competitive Rivalry

3.3.2 SWOT Analysis; By Factor (Political & Legal, Economic, and Technological)

3.3.2.1 Political Landscape

3.3.2.2 Economic Landscape

3.3.2.3 Social Landscape

3.3.2.4 Technology Landscape

3.3.3 Value Chain Analysis

3.3.4 Trend Analysis

3.3.5 Gap Analysis

3.3.6 Cost Analysis

4 GLOBAL IOT IN CHEMICAL MARKET, BY TECHNOLOGY

4.1 Introduction

4.2 IoT in Chemical Market: Technology Scope Key Takeaways

4.3 Revenue Growth Analysis, 2023 & 2029

4.4 Enabling Technology

4.4.1 Enabling Technology Market Estimates and Forecast, 2021-2029 (USD Million)

4.5 Operational Technology

4.5.1 Operational Technology Market Estimates and Forecast, 2021-2029 (USD Million)

5 GLOBAL IOT IN CHEMICAL MARKET, BY APPLICATION

5.1 Introduction

5.2 IoT in Chemical Market: Application Scope Key Takeaways

5.3 Revenue Growth Analysis, 2023 & 2029

5.4 Chemicals

5.4.1 Chemicals Market Estimates and Forecast, 2021-2029 (USD Million)

5.5 Food & Beverages

5.5.1 Food & Beverages Market Estimates and Forecast, 2021-2029 (USD Million)

5.6 Mining & Metals

5.6.1 Mining & Metals Market Estimates and Forecast, 2021-2029 (USD Million)

5.7 Paper & Pulp

5.7.1 Paper & Pulp Market Estimates and Forecast, 2021-2029 (USD Million)

5.8 Pharmaceuticals

5.8.1 Pharmaceuticals Market Estimates and Forecast, 2021-2029 (USD Million)

6 GLOBAL IOT IN CHEMICAL MARKET, BY REGION

6.1 Introduction

6.2 North America IoT in Chemical Market Estimates and Forecast, 2021-2029 (USD Million)

6.2.1 By Technology

6.2.2 By Application

6.2.3 By Country

6.2.3.1 U.S. IoT in Chemical Market Estimates and Forecast, 2021-2029 (USD Million)

6.2.3.1.1 By Technology

6.2.3.1.2 By Application

6.2.3.2 Canada IoT in Chemical Market Estimates and Forecast, 2021-2029 (USD Million)

6.2.3.2.1 By Technology

6.2.3.2.2 By Application

6.2.3.3 Mexico IoT in Chemical Market Estimates and Forecast, 2021-2029 (USD Million)

6.2.3.3.1 By Technology

6.2.3.3.2 By Application

6.3 Europe IoT in Chemical Market Estimates and Forecast, 2021-2029 (USD Million)

6.3.1 By Technology

6.3.2 By Application

6.3.3 By Country

6.3.3.1 Germany IoT in Chemical Market Estimates and Forecast, 2021-2029 (USD Million)

6.3.3.1.1 By Technology

6.3.3.1.2 By Application

6.3.3.2 U.K. IoT in Chemical Market Estimates and Forecast, 2021-2029 (USD Million)

6.3.3.2.1 By Technology

6.3.3.2.2 By Application

6.3.3.3 France IoT in Chemical Market Estimates and Forecast, 2021-2029 (USD Million)

6.3.3.3.1 By Technology

6.3.3.3.2 By Application

6.3.3.4 Italy IoT in Chemical Market Estimates and Forecast, 2021-2029 (USD Million)

6.3.3.4.1 By Technology

6.3.3.4.2 By Application

6.3.3.5 Spain IoT in Chemical Market Estimates and Forecast, 2021-2029 (USD Million)

6.3.3.5.1 By Technology

6.3.3.5.2 By Application

6.3.3.6 Netherlands IoT in Chemical Market Estimates and Forecast, 2021-2029 (USD Million)

6.3.3.6.1 By Technology

6.3.3.6.2 By Application

6.3.3.7 Rest of Europe IoT in Chemical Market Estimates and Forecast, 2021-2029 (USD Million)

6.3.3.6.1 By Technology

6.3.3.6.2 By Application

6.4 Asia Pacific IoT in Chemical Market Estimates and Forecast, 2021-2029 (USD Million)

6.4.1 By Technology

6.4.2 By Application

6.4.3 By Country

6.4.3.1 China IoT in Chemical Market Estimates and Forecast, 2021-2029 (USD Million)

6.4.3.1.1 By Technology

6.4.3.1.2 By Application

6.4.3.2 Japan IoT in Chemical Market Estimates and Forecast, 2021-2029 (USD Million)

6.4.3.2.1 By Technology

6.4.3.2.2 By Application

6.4.3.3 India IoT in Chemical Market Estimates and Forecast, 2021-2029 (USD Million)

6.4.3.3.1 By Technology

6.4.3.3.2 By Application

6.4.3.4 South Korea IoT in Chemical Market Estimates and Forecast, 2021-2029 (USD Million)

6.4.3.4.1 By Technology

6.4.3.4.2 By Application

6.4.3.5 Singapore IoT in Chemical Market Estimates and Forecast, 2021-2029 (USD Million)

6.4.3.5.1 By Technology

6.4.3.5.2 By Application

6.4.3.6 Malaysia IoT in Chemical Market Estimates and Forecast, 2021-2029 (USD Million)

6.4.3.6.1 By Technology

6.4.3.6.2 By Application

6.4.3.7 Thailand IoT in Chemical Market Estimates and Forecast, 2021-2029 (USD Million)

6.4.3.6.1 By Technology

6.4.3.6.2 By Application

6.4.3.8 Indonesia IoT in Chemical Market Estimates and Forecast, 2021-2029 (USD Million)

6.4.3.7.1 By Technology

6.4.3.7.2 By Application

6.4.3.9 Vietnam IoT in Chemical Market Estimates and Forecast, 2021-2029 (USD Million)

6.4.3.8.1 By Technology

6.4.3.8.2 By Application

6.4.3.10 Taiwan IoT in Chemical Market Estimates and Forecast, 2021-2029 (USD Million)

6.4.3.10.1 By Technology

6.4.3.10.2 By Application

6.4.3.11 Rest of Asia Pacific IoT in Chemical Market Estimates and Forecast, 2021-2029 (USD Million)

6.4.3.11.1 By Technology

6.4.3.11.2 By Application

6.5 Middle East and Africa IoT in Chemical Market Estimates and Forecast, 2021-2029 (USD Million)

6.5.1 By Technology

6.5.2 By Application

6.5.3 By Country

6.5.3.1 Saudi Arabia IoT in Chemical Market Estimates and Forecast, 2021-2029 (USD Million)

6.5.3.1.1 By Technology

6.5.3.1.2 By Application

6.5.3.2 U.A.E. IoT in Chemical Market Estimates and Forecast, 2021-2029 (USD Million)

6.5.3.2.1 By Technology

6.5.3.2.2 By Application

6.5.3.3 Israel IoT in Chemical Market Estimates and Forecast, 2021-2029 (USD Million)

6.5.3.3.1 By Technology

6.5.3.3.2 By Application

6.5.3.4 South Africa IoT in Chemical Market Estimates and Forecast, 2021-2029 (USD Million)

6.5.3.4.1 By Technology

6.5.3.4.2 By Application

6.5.3.5 Rest of Middle East and Africa IoT in Chemical Market Estimates and Forecast, 2021-2029 (USD Million)

6.5.3.5.1 By Technology

6.5.3.5.2 By Application

6.6 Central & South America IoT in Chemical Market Estimates and Forecast, 2021-2029 (USD Million)

6.6.1 By Technology

6.6.2 By Application

6.6.3 By Country

6.6.3.1 Brazil IoT in Chemical Market Estimates and Forecast, 2021-2029 (USD Million)

6.6.3.1.1 By Technology

6.6.3.1.2 By Application

6.6.3.2 Argentina IoT in Chemical Market Estimates and Forecast, 2021-2029 (USD Million)

6.6.3.2.1 By Technology

6.6.3.2.2 By Application

6.6.3.3 Chile IoT in Chemical Market Estimates and Forecast, 2021-2029 (USD Million)

6.6.3.3.1 By Technology

6.6.3.3.2 By Application

6.6.3.3 Rest of Central & South America IoT in Chemical Market Estimates and Forecast, 2021-2029 (USD Million)

6.6.3.3.1 By Technology

6.6.3.3.2 By Application

7 COMPETITIVE LANDCAPE

7.1 Company Market Share Analysis

7.2 Four Quadrant Positioning Matrix

7.2.1 Market Leaders

7.2.2 Market Visionaries

7.2.3 Market Challengers

7.2.4 Niche Market Players

7.3 Vendor Landscape

7.3.1 North America

7.3.2 Europe

7.3.3 Asia Pacific

7.3.4 Rest of the World

7.4 Company Profiles

7.4.1 ABB Ltd.

7.4.1.1 Business Description & Financial Analysis

7.4.1.2 SWOT Analysis

7.4.1.3 Products & Services Offered

7.4.1.4 Strategic Alliances between Business Partners

7.4.2 Atos SE

7.4.2.1 Business Description & Financial Analysis

7.4.2.2 SWOT Analysis

7.4.2.3 Products & Services Offered

7.4.2.4 Strategic Alliances between Business Partners

7.4.3 Claroty Ltd.

7.4.3.1 Business Description & Financial Analysis

7.4.3.2 SWOT Analysis

7.4.3.3 Products & Services Offered

7.4.3.4 Strategic Alliances between Business Partners

7.4.4 Denso Corporation

7.4.4.1 Business Description & Financial Analysis

7.4.4.2 SWOT Analysis

7.4.4.3 Products & Services Offered

7.4.4.4 Strategic Alliances between Business Partners

7.4.5 Hewlett Packard Enterprise Company

7.4.5.1 Business Description & Financial Analysis

7.4.5.2 SWOT Analysis

7.4.5.3 Products & Services Offered

7.4.5.4 Strategic Alliances between Business Partners

7.4.6 MICROSOFT CORPORATION

7.4.6.1 Business Description & Financial Analysis

7.4.6.2 SWOT Analysis

7.4.6.3 Products & Services Offered

7.4.6.4 Strategic Alliances between Business Partners

7.4.7 Mitsubishi Electric Corporation

7.4.7.1 Business Description & Financial Analysis

7.4.7.2 SWOT Analysis

7.4.7.3 Products & Services Offered

7.4.7.4 Strategic Alliances between Business Partners

7.4.8 Rockwell Automation, Inc.

7.4.8.1 Business Description & Financial Analysis

7.4.8.2 SWOT Analysis

7.4.8.3 Products & Services Offered

7.4.8.4 Strategic Alliances between Business Partners

7.4.9 Samsung Electronics Co. Ltd.

7.4.9.1 Business Description & Financial Analysis

7.4.9.2 SWOT Analysis

7.4.9.3 Products & Services Offered

7.4.9.4 Strategic Alliances between Business Partners

7.4.10 Schneider Electric SE

7.4.10.1 Business Description & Financial Analysis

7.4.10.2 SWOT Analysis

7.4.10.3 Products & Services Offered

7.4.10.4 Strategic Alliances between Business Partners

7.4.11 Other Companies

7.4.11.1 Business Description & Financial Analysis

7.4.11.2 SWOT Analysis

7.4.11.3 Products & Services Offered

7.4.11.4 Strategic Alliances between Business Partners

8 RESEARCH METHODOLOGY

8.1 Market Introduction

8.1.1 Market Definition

8.1.2 Market Scope & Segmentation

8.2 Information Procurement

8.2.1 Secondary Research

8.2.1.1 Purchased Databases

8.2.1.2 GMEs Internal Data Repository

8.2.1.3 Secondary Resources & Third Party Perspectives

8.2.1.4 Company Information Sources

8.2.2 Primary Research

8.2.2.1 Various Types of Respondents for Primary Interviews

8.2.2.2 Number of Interviews Conducted throughout the Research Process

8.2.2.3 Primary Stakeholders

8.2.2.4 Discussion Guide for Primary Participants

8.2.3 Expert Panels

8.2.3.1 Expert Panels Across 30+ Industry

8.2.4 Paid Local Experts

8.2.4.1 Paid Local Experts Across 30+ Industry Across each Region

8.3 Market Estimation

8.3.1 Top-Down Approach

8.3.1.1 Macro-Economic Indicators Considered

8.3.1.2 Micro-Economic Indicators Considered

8.3.2 Bottom Up Approach

8.3.2.1 Company Share Analysis Approach

8.3.2.2 Estimation of Potential Product Sales

8.4 Data Triangulation

8.4.1 Data Collection

8.4.2 Time Series, Cross Sectional & Panel Data Analysis

8.4.3 Cluster Analysis

8.5 Analysis and Output

8.5.1 Inhouse AI Based Real Time Analytics Tool

8.5.2 Output From Desk & Primary Research

8.6 Research Assumptions & Limitations

8.6.1 Research Assumptions

8.6.2 Research Limitations

LIST OF TABLES

1 Global IoT in Chemical Market, By Technology, 2021-2029 (USD Million)

2 Enabling Technology Market, By Region, 2021-2029 (USD Million)

3 Operational Technology Market, By Region, 2021-2029 (USD Million)

4 Global IoT in Chemical Market, By Application, 2021-2029 (USD Million)

5 Chemicals Market, By Region, 2021-2029 (USD Million)

6 Food & Beverages Market, By Region, 2021-2029 (USD Million)

7 Mining & Metals Market, By Region, 2021-2029 (USD Million)

8 Paper & Pulp Market, By Region, 2021-2029 (USD Million)

9 Pharmaceuticals Market, By Region, 2021-2029 (USD Million)

10 Regional Analysis, 2021-2029 (USD Million)

11 North America IoT in Chemical Market, By Technology, 2021-2029 (USD Million)

12 North America IoT in Chemical Market, By Application, 2021-2029 (USD Million)

13 North America IoT in Chemical Market, By Country, 2021-2029 (USD Million)

14 U.S. IoT in Chemical Market, By Technology, 2021-2029 (USD Million)

15 U.S. IoT in Chemical Market, By Application, 2021-2029 (USD Million)

16 Canada IoT in Chemical Market, By Technology, 2021-2029 (USD Million)

17 Canada IoT in Chemical Market, By Application, 2021-2029 (USD Million)

18 Mexico IoT in Chemical Market, By Technology, 2021-2029 (USD Million)

19 Mexico IoT in Chemical Market, By Application, 2021-2029 (USD Million)

20 Europe IoT in Chemical Market, By Technology, 2021-2029 (USD Million)

21 Europe IoT in Chemical Market, By Application, 2021-2029 (USD Million)

22 Europe IoT in Chemical Market, By Country, 2021-2029 (USD Million)

23 Germany IoT in Chemical Market, By Technology, 2021-2029 (USD Million)

24 Germany IoT in Chemical Market, By Application, 2021-2029 (USD Million)

25 U.K. IoT in Chemical Market, By Technology, 2021-2029 (USD Million)

26 U.K. IoT in Chemical Market, By Application, 2021-2029 (USD Million)

27 France IoT in Chemical Market, By Technology, 2021-2029 (USD Million)

28 France IoT in Chemical Market, By Application, 2021-2029 (USD Million)

29 Italy IoT in Chemical Market, By Technology, 2021-2029 (USD Million)

30 Italy IoT in Chemical Market, By Application, 2021-2029 (USD Million)

31 Spain IoT in Chemical Market, By Technology, 2021-2029 (USD Million)

32 Spain IoT in Chemical Market, By Application, 2021-2029 (USD Million)

33 Netherlands IoT in Chemical Market, By Technology, 2021-2029 (USD Million)

34 Netherlands IoT in Chemical Market, By Application, 2021-2029 (USD Million)

35 Rest Of Europe IoT in Chemical Market, By Technology, 2021-2029 (USD Million)

36 Rest Of Europe IoT in Chemical Market, By Application, 2021-2029 (USD Million)

37 Asia Pacific IoT in Chemical Market, By Technology, 2021-2029 (USD Million)

38 Asia Pacific IoT in Chemical Market, By Application, 2021-2029 (USD Million)

39 Asia Pacific IoT in Chemical Market, By Country, 2021-2029 (USD Million)

40 China IoT in Chemical Market, By Technology, 2021-2029 (USD Million)

41 China IoT in Chemical Market, By Application, 2021-2029 (USD Million)

42 Japan IoT in Chemical Market, By Technology, 2021-2029 (USD Million)

43 Japan IoT in Chemical Market, By Application, 2021-2029 (USD Million)

44 India IoT in Chemical Market, By Technology, 2021-2029 (USD Million)

45 India IoT in Chemical Market, By Application, 2021-2029 (USD Million)

46 South Korea IoT in Chemical Market, By Technology, 2021-2029 (USD Million)

47 South Korea IoT in Chemical Market, By Application, 2021-2029 (USD Million)

48 Singapore IoT in Chemical Market, By Technology, 2021-2029 (USD Million)

49 Singapore IoT in Chemical Market, By Application, 2021-2029 (USD Million)

50 Thailand IoT in Chemical Market, By Technology, 2021-2029 (USD Million)

51 Thailand IoT in Chemical Market, By Application, 2021-2029 (USD Million)

52 Malaysia IoT in Chemical Market, By Technology, 2021-2029 (USD Million)

53 Malaysia IoT in Chemical Market, By Application, 2021-2029 (USD Million)

54 Indonesia IoT in Chemical Market, By Technology, 2021-2029 (USD Million)

55 Indonesia IoT in Chemical Market, By Application, 2021-2029 (USD Million)

56 Vietnam IoT in Chemical Market, By Technology, 2021-2029 (USD Million)

57 Vietnam IoT in Chemical Market, By Application, 2021-2029 (USD Million)

58 Taiwan IoT in Chemical Market, By Technology, 2021-2029 (USD Million)

59 Taiwan IoT in Chemical Market, By Application, 2021-2029 (USD Million)

60 Rest of APAC IoT in Chemical Market, By Technology, 2021-2029 (USD Million)

61 Rest of APAC IoT in Chemical Market, By Application, 2021-2029 (USD Million)

62 Middle East and Africa IoT in Chemical Market, By Technology, 2021-2029 (USD Million)

63 Middle East and Africa IoT in Chemical Market, By Application, 2021-2029 (USD Million)

64 Middle East and Africa IoT in Chemical Market, By country, 2021-2029 (USD Million)

65 Saudi Arabia IoT in Chemical Market, By Technology, 2021-2029 (USD Million)

66 Saudi Arabia IoT in Chemical Market, By Application, 2021-2029 (USD Million)

67 UAE IoT in Chemical Market, By Technology, 2021-2029 (USD Million)

68 UAE IoT in Chemical Market, By Application, 2021-2029 (USD Million)

69 Israel IoT in Chemical Market, By Technology, 2021-2029 (USD Million)

70 Israel IoT in Chemical Market, By Application, 2021-2029 (USD Million)

71 South Africa IoT in Chemical Market, By Technology, 2021-2029 (USD Million)

72 South Africa IoT in Chemical Market, By Application, 2021-2029 (USD Million)

73 Rest Of Middle East and Africa IoT in Chemical Market, By Technology, 2021-2029 (USD Million)

74 Rest Of Middle East and Africa IoT in Chemical Market, By Application, 2021-2029 (USD Million)

75 Central & South America IoT in Chemical Market, By Technology, 2021-2029 (USD Million)

76 Central & South America IoT in Chemical Market, By Application, 2021-2029 (USD Million)

77 Central & South America IoT in Chemical Market, By Country, 2021-2029 (USD Million)

78 Brazil IoT in Chemical Market, By Technology, 2021-2029 (USD Million)

79 Brazil IoT in Chemical Market, By Application, 2021-2029 (USD Million)

80 Chile IoT in Chemical Market, By Technology, 2021-2029 (USD Million)

81 Chile IoT in Chemical Market, By Application, 2021-2029 (USD Million)

82 Argentina IoT in Chemical Market, By Technology, 2021-2029 (USD Million)

83 Argentina IoT in Chemical Market, By Application, 2021-2029 (USD Million)

84 Rest Of Central & South America IoT in Chemical Market, By Technology, 2021-2029 (USD Million)

85 Rest Of Central & South America IoT in Chemical Market, By Application, 2021-2029 (USD Million)

86 ABB Ltd.: Products & Services Offering

87 Atos SE: Products & Services Offering

88 Claroty Ltd.: Products & Services Offering

89 Denso Corporation: Products & Services Offering

90 Hewlett Packard Enterprise Company: Products & Services Offering

91 MICROSOFT CORPORATION: Products & Services Offering

92 Mitsubishi Electric Corporation : Products & Services Offering

93 Rockwell Automation, Inc.: Products & Services Offering

94 Samsung Electronics Co. Ltd.: Products & Services Offering

95 Schneider Electric SE: Products & Services Offering

96 Other Companies: Products & Services Offering

LIST OF FIGURES

1 Global IoT in Chemical Market Overview

2 Global IoT in Chemical Market Value From 2021-2029 (USD Million)

3 Global IoT in Chemical Market Share, By Technology (2023)

4 Global IoT in Chemical Market Share, By Application (2023)

5 Global IoT in Chemical Market, By Region (Asia Pacific Market)

6 Technological Trends In Global IoT in Chemical Market

7 Four Quadrant Competitor Positioning Matrix

8 Impact Of Macro & Micro Indicators On The Market

9 Impact Of Key Drivers On The Global IoT in Chemical Market

10 Impact Of Challenges On The Global IoT in Chemical Market

11 Porter’s Five Forces Analysis

12 Global IoT in Chemical Market: By Technology Scope Key Takeaways

13 Global IoT in Chemical Market, By Technology Segment: Revenue Growth Analysis

14 Enabling Technology Market, By Region, 2021-2029 (USD Million)

15 Operational Technology Market, By Region, 2021-2029 (USD Million) Global IoT in Chemical Market: By Application Scope Key Takeaways

16 Global IoT in Chemical Market, By Application Segment: Revenue Growth Analysis

17 Chemicals Market, By Region, 2021-2029 (USD Million)

18 Food & Beverages Market, By Region, 2021-2029 (USD Million)

19 Mining & Metals Market, By Region, 2021-2029 (USD Million)

20 Paper & Pulp Market, By Region, 2021-2029 (USD Million)

21 Pharmaceuticals Market, By Region, 2021-2029 (USD Million)

22 Regional Segment: Revenue Growth Analysis

23 Global IoT in Chemical Market: Regional Analysis

24 North America IoT in Chemical Market Overview

25 North America IoT in Chemical Market, By Technology

26 North America IoT in Chemical Market, By Application

27 North America IoT in Chemical Market, By Country

28 U.S. IoT in Chemical Market, By Technology

29 U.S. IoT in Chemical Market, By Application

30 Canada IoT in Chemical Market, By Technology

31 Canada IoT in Chemical Market, By Application

32 Mexico IoT in Chemical Market, By Technology

33 Mexico IoT in Chemical Market, By Application

34 Four Quadrant Positioning Matrix

35 Company Market Share Analysis

36 ABB Ltd.: Company Snapshot

37 ABB Ltd.: SWOT Analysis

38 ABB Ltd.: Geographic Presence

39 Atos SE: Company Snapshot

40 Atos SE: SWOT Analysis

41 Atos SE: Geographic Presence

42 Claroty Ltd.: Company Snapshot

43 Claroty Ltd.: SWOT Analysis

44 Claroty Ltd.: Geographic Presence

45 Denso Corporation: Company Snapshot

46 Denso Corporation: Swot Analysis

47 Denso Corporation: Geographic Presence

48 Hewlett Packard Enterprise Company: Company Snapshot

49 Hewlett Packard Enterprise Company: SWOT Analysis

50 Hewlett Packard Enterprise Company: Geographic Presence

51 MICROSOFT CORPORATION: Company Snapshot

52 MICROSOFT CORPORATION: SWOT Analysis

53 MICROSOFT CORPORATION: Geographic Presence

54 Mitsubishi Electric Corporation : Company Snapshot

55 Mitsubishi Electric Corporation : SWOT Analysis

56 Mitsubishi Electric Corporation : Geographic Presence

57 Rockwell Automation, Inc.: Company Snapshot

58 Rockwell Automation, Inc.: SWOT Analysis

59 Rockwell Automation, Inc.: Geographic Presence

60 Samsung Electronics Co. Ltd..: Company Snapshot

61 Samsung Electronics Co. Ltd..: SWOT Analysis

62 Samsung Electronics Co. Ltd..: Geographic Presence

63 Schneider Electric SE: Company Snapshot

64 Schneider Electric SE: SWOT Analysis

65 Schneider Electric SE: Geographic Presence

66 Other Companies: Company Snapshot

67 Other Companies: SWOT Analysis

68 Other Companies: Geographic Presence

The Global IOT in Chemical Market has been studied from the year 2019 till 2029. However, the CAGR provided in the report is from the year 2024 to 2029. The research methodology involved three stages: Desk research, Primary research, and Analysis & Output from the entire research process.

The desk research involved a robust background study which meant referring to paid and unpaid databases to understand the market dynamics; mapping contracts from press releases; identifying the key players in the market, studying their product portfolio, competition level, annual reports/SEC filings & investor presentations; and learning the demand and supply-side analysis for the IOT in Chemical Market.

The primary research activity included telephonic conversations with more than 50 tier 1 industry consultants, distributors, and end-use product manufacturers.

Finally, based on the above thorough research process, an in-depth analysis was carried out considering the following aspects: market attractiveness, current & future market trends, market share analysis, SWOT analysis of the company and customer analytics.

Frequently Asked Questions

Tailor made solutions just for you

80% of our clients seek made-to-order reports. How do you want us to tailor yours?

OUR CLIENTS